Pig manure with 95% moisture content is returned to compost without any secondary materials! (Client: Nakamura Sangyo)

Here is an introduction to a composting plant that is ideal for composting manure with high moisture content, such as livestock manure.

- Products Introduced

- Easy JetComposting Plant

- Client and Location

- Nagasaki Prefecture / Nakamura Sangyo

- Processed Material

- Pig Manure 10t/day The manure from 1,400 sows, separated into solid and liquid (moisture content 95%)

- Issue

- Due to the 95% moisture content of pig manure, fermentation temperature does not rise easily and composting does not proceed

Overview of Composting at Nakamura Sangyo

Nakamura Industries in Nagasaki Prefecture raises 1,400 sows (total 15,000 pigs) using a slatted floor system. The collected manure is separated into solids and liquids, with the solids having a moisture content of 95% and an output of 10 tons per day (the liquid is treated as wastewater). Previously, they used wood chips as an additive for composting.

The pig manure with 95% moisture content being put in

Introduction of the “Easy Jet”

By switching the ventilation method from a blower to the Easy Jet at the beginning of fermentation, the fermentation temperature increased significantly.

Half of the 10 tons of pig manure per day, or 5 tons, is fermented and dried endlessly using an Easy Jet and rotary agitator.

By doing so, we were able to reduce the moisture content of the raw material from 95% to 35%.

The raw material, now ready for use as return compost, can be utilized as bedding in the piggery.

With rising costs of wood chips, more facilities are now utilizing their own compost.

State of Compost After Fermentation and Drying (Moisture Content 35%)

Specific Operation Method

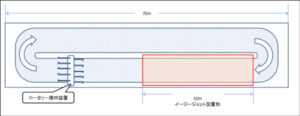

Layout of the Rotary Fermentation Tank

The layout of the rotary fermentation tank is shown above. The Easy Jet is installed on 20% of the floor area (32 meters, indicated by the red outline).

High-moisture manure is added daily from the top of the compost.

The moisture content of the high-moisture manure decreases to 45% by the time it completes one rotation of the rotary tank, allowing for the addition of more high-moisture manure without issues.

Advantages of Introducing the “Easy Jet”

The superiority of this method is that:

(1)No secondary materials are used (all of the compost can be used), so there is no need to purchase secondary materials.

(2) There is almost no work to take out the compost.

Particularly, (1) significantly contributes to cost reduction due to the recent increase in the cost of wood-based materials.

In a typical composting method used in composting facilities, processing 10 tons per day of manure with a moisture content of 95% requires 5.6 tons (about 15 m³ to 20 m³ per day) of auxiliary materials; thus, calculating at 800 yen per m³, the annual cost for purchasing auxiliary materials alone exceeds 4 million yen.

Additionally, if you want to ferment the compost within 90 days, a composting facility of over 1,000㎡ will be necessary.

EasyJet not only contributes to cost reduction but also, compared to general rotary systems, maintains a higher fermentation temperature even during winter, which promotes moisture evaporation from the raw manure and enables sustained, stable processing.

Comparison of fermentation temperatures with and without “Easy Jet”

Left: Without Easy Jet Right: With Easy Jet

The above comparison was conducted under the same conditions of using the same raw materials and starting at the same time, comparing sections with and without the use of Easy Jet.

As shown, there was a significant difference in fermentation temperatures and a clear difference in dryness. When the fermentation temperature is lower, the moisture evaporation effect also decreases. Consequently, in winter, the drying efficiency of composting tanks without Easy Jet drops by 30%. (Normally, 5 tons of manure can be processed per day, but in winter, only about 3.5 tons per day can be processed. Any more than this would not yield usable compost.)

In this case, if an additional unit is installed, the introduction costs for a composting house of approximately 400 m² and a rotary mixer would exceed 10 million yen, and even if the unit is added, if the fermentation temperature does not increase, issues related to biosecurity will remain.

With the Easy Jet, fermentation temperatures can be raised well and costs can be reduced.

A decrease in manure processing capacity significantly impacts the farm’s environmental and disease prevention aspects, so it is recommended to take action promptly.

Easy Jet can be installed in existing fermentation facilities, so please feel free to contact our company for more information.

Introduction of the Product

Composting Equipment

Easy Jet

Composting Equipment that requires no turning

A special nozzle supplies oxygen to the inside of the compost, eliminating the need for heavy machinery to turn the compost around. High-temperature fermentation in winter is realized, enabling production of high-quality compost.

Composting Complex Equipment

Composting Plant

Balancing Odor Control and Labor Reduction

Combining MIRAIE's technology and know-how, we propose the optimal Composting Plant tailored to your materials and challenges. It achieves stable production with reduced costs and labor.

writer

CORPORATIONMIRAIE

We are a plant manufacturer specializing in composting and recycling equipment. We provide comprehensive support to customers facing composting and odor issues and strive to strengthen production systems to improve productivity.

Facebook

Facebook X

X Hatena

Hatena Poket

Poket