Mixing materials of different specific gravity in a short time and automating the granulation mixing process reduces work costs by 90% or more.

The cumbersome mixing process of raw materials and auxiliary materials (preparation work), which used to be performed by heavy machinery, is now automated. Materials with different specific gravities and high molecular sludge, which were difficult to mix uniformly before, can now be processed and granulated in a short time. The system features a simple, corrosion-resistant structure that provides stable performance over a long period. Automation also allows for significant reductions in labor and fuel costs.

Compatible with Various Organic Materials

The system can handle all types of organic materials, including high molecular sludge that is difficult to mix with heavy machinery.

-

Sludge + Sawdust -

Sludge + Rice Husk -

Sludge + Returned Compost -

Horse Manure + Cattle Manure -

Food Waste + Wood Chips

Mixing uniformly and accelerating composting in a short time

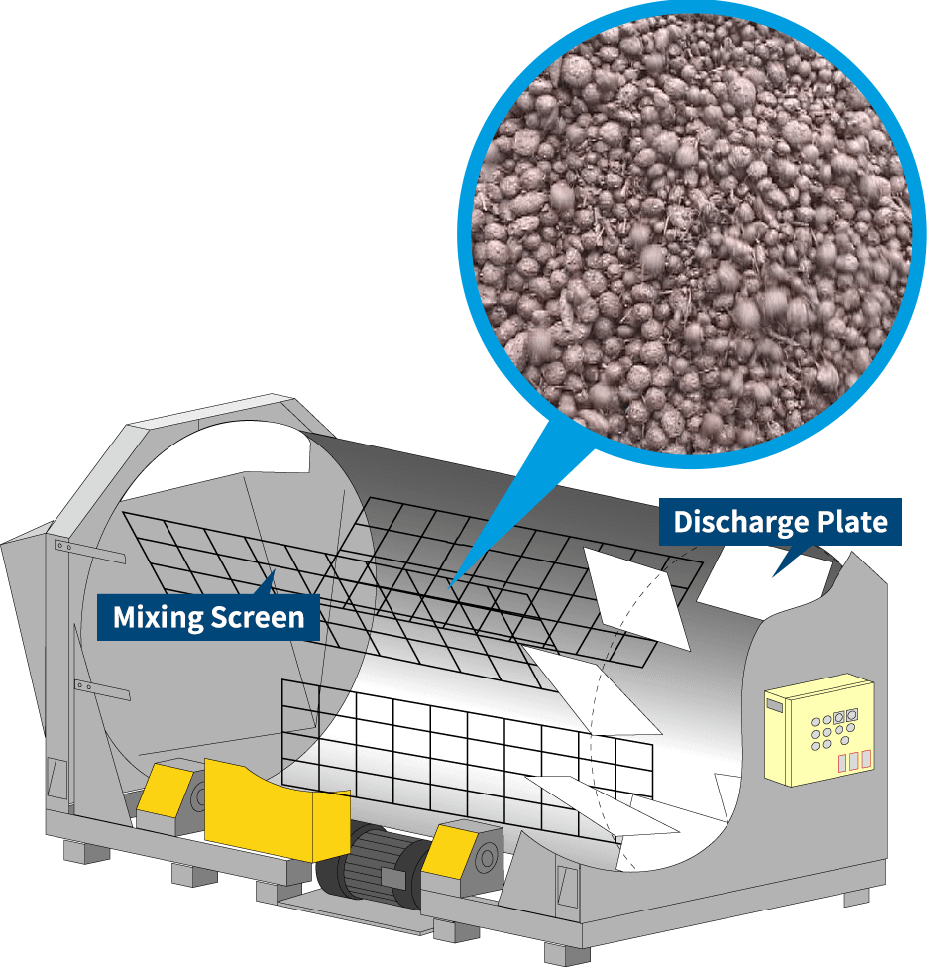

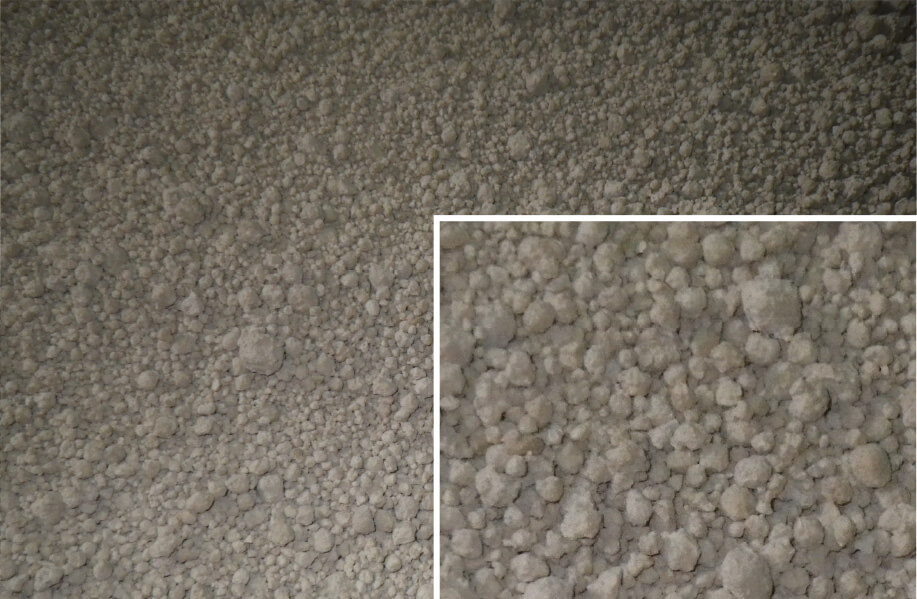

In the first stage of composting, which involves the preparation process, adjusting specific gravity and moisture content for uniform mixing is crucial. The C mode achieves automatic stirring and discharge with the push of a button. Equipped with special blades, it can process up to 3 m³ or 2.5 tons of materials per batch in 10 to 30 minutes. Unlike conventional methods using heavy machinery, which often result in clumping, this system produces uniformly granulated compost. Proper mixing promotes high-quality compost production.

By granulating the compost materials, the surface area of the raw materials is increased, which promotes aerobic fermentation.

BeforeFermentation failure due to lack of air passage

Mixing

by heavy equipment

20min.

Afteraerobic fermentation is promoted

Mixing

by C-mode

5min.

Compared to conventional methods,

labor costs are reduced by 97%.

Compared to traditional heavy machinery for preparation tasks, significant reductions in labor and fuel costs can be achieved. With a daily processing volume of 30 tons, labor costs decrease by 97%. Additionally, uniform mixing promotes subsequent aerobic fermentation, leading to a shorter composting period and reduced odor, contributing to overall cost savings.

Video Introduction of C-Mode Case Studies

Stable performance and long life

C-Mode features a compact design that is space-efficient, equivalent to the size of a single vehicle, and boasts a simple, corrosion-resistant structure. It prevents material sealing and overloading issues. Additionally, it effectively dries high-viscosity raw materials, preventing entanglement with the machine and ensuring stable performance over an extended period.

Product Overview

| Model | C20PH |

|---|---|

| Capacity※ | Max 3 m³ per batch, Max 2.5 tons per batch |

| Dimensions | Width 2,230 mm, Length 4,995 mm, Height 2,686 mm |

| Weight | 3,700kg |

| Electrical Capacity 3-phase | 200V, 5.5 kW |

Option

- Extended Inlet

- Adjustable wide input opening to accommodate large heavy machinery

- Inlet Mirror

- Safe visibility even in blind spots

- Remote Control

- Operable while remaining seated in the heavy machinery

- Control Panel

- One button automates the entire process from start to finish.

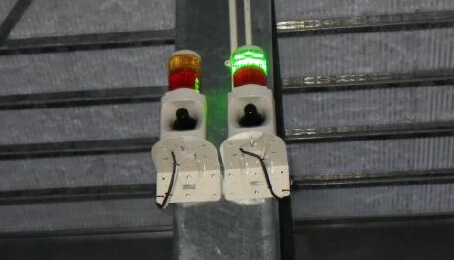

- Drive mode notification lamp.

- You can check the C-Mode driving status even from a remote location.

- Sorting conveyor

- Transports materials to multiple fermentation tanks.

- Ancillary Equipment

- Mixture Heating Tank

- Increases the fermentation temperature of the mixture within 24 hours.

- Ancillary Equipment

Additionally, we offer discharge acceleration units, sludge screens, all-stainless steel components, and anti-corrosion coatings. Please feel free to consult us.