A lineup of equipment that makes composting more convenient by addressing individual needs

MIRAIE offers a range of equipment to meet various composting needs. Our consulting engineers first conduct a hearing to understand your requirements and challenges, such as scale, processing volume, and cost. After assessing the current situation, we propose the most suitable equipment to contribute to improved productivity. These systems can also be combined with existing equipment.

-

Pre-Treatment

Food Waste Bag Breaking and Sorting Device

-

Pre-Treatment

Small-Scale Raw Material Mixing Device

-

Pre-Treatment

Used Mushroom Bed Crushing and Sorting Device

-

Post-Treatment

Semi-Automatic Bagging Device

-

Other

Sorting Conveyor

Pre-Treatment

Food Waste Bag Breaking and Sorting Device (MMS552)

Removes 99.6% of foreign matter while finely grinding food waste

Plastic bags and food trays that are disposed of with food waste hinder composting. By simply feeding food waste into this device with foreign matter, it is instantly ground and sorted, with foreign matter removed by air power. It boasts a high accuracy rate of 99.9% for foreign matter removal. Additionally, grinding promotes aerobic fermentation, leading to a shorter composting period and odor prevention.

●Maximum processing capacity 4m³

●Electrical capacity 3-phase 200V 5.5kW

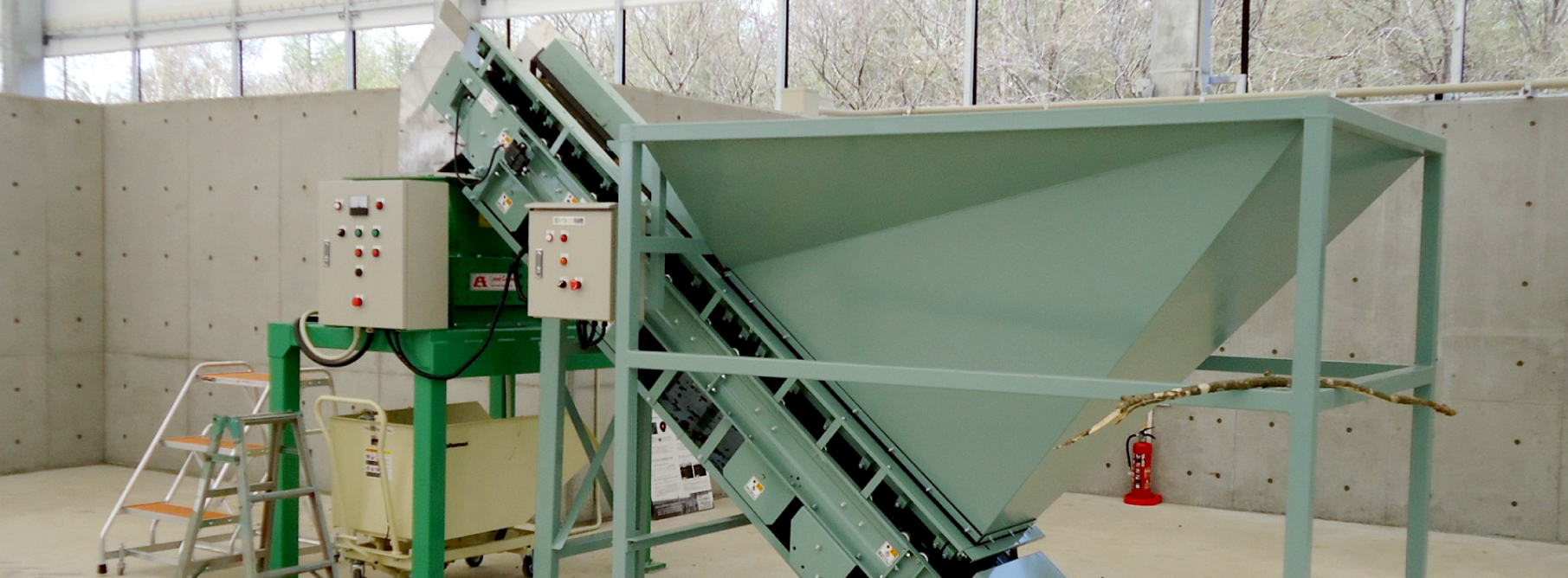

Pre-Treatment

Small-Scale Raw Material Mixing Device (Quantitative supply device)

A raw material mixing device that allows direct loading from a loader.

This raw material mixing device helps reduce labor in preparation work before composting. It allows direct loading from a loader and is designed for small-scale operations, with a processing capacity of 1 to 5 m³ per batch for mixing small quantities of raw materials. When equipped with a separately sold conveying device, it can automatically transport and discharge the mixed materials. It can also be used as a quantitative supply device.

●Maximum processing capacity 1 to 5m³

Pre-Treatment

Used Mushroom Bed Crushing and Sorting Device(with MKCM5 conveyor)

Instantly crushes and sorts foreign matter before composting

Used mushroom beds, which can be reused as compost, are initially in a hard state. They need to be crushed before composting. This device automatically sorts and removes foreign matter using air power while rapidly crushing the used mushroom beds. It reduces the labor involved in removing foreign matter and crushing, promoting smoother fermentation.

●Size 2150×950×1300mm

●Processing Capacity 2.5kg substrate: 450 pieces/hour, 1.2kg substrate: 600 pieces/hour

●Electrical Capacity 3-phase 200V 3.7kW

A quantitative supply device (sold separately) can be installed for automatic feeding.

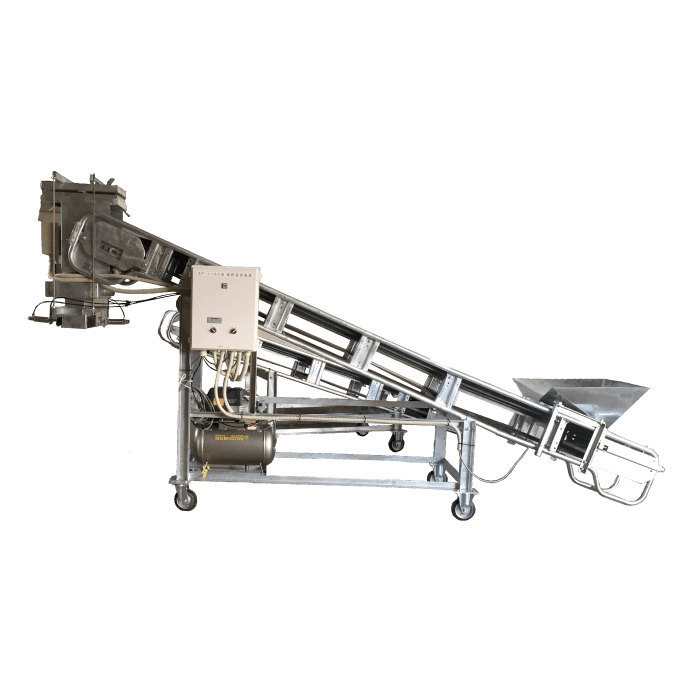

Post-Treatment

Semi-Automatic Bagging Device

Semi-automatically bags the completed compost

The finished compost is placed on the conveyor, the bags are set in the equipment, and the foot treadle device is stepped on, and the bags are then automatically packed. With computer-managed weighing, it is reliable. It is also more affordable compared to fully automated bagging devices, making it easier to implement. This reduces the labor involved in bagging compost and helps improve sales revenue.

●Processing Capacity 40–60 bags/hour

●Size 2500×1960×940mm

Other

Sorting Conveyor

Conveys processed material to multiple fermentation tanks by controlling the conveyor

This device automates the entire composting process using a conveyor. Processed materials are directly conveyed to fermentation tanks via the conveyor. With computer control, it can automatically distribute materials to multiple fermentation tanks. It significantly aids in labor-saving by reducing the need for heavy machinery and manual handling.

●Processing Capacity 1–20m³/hour