Revolutionary Aeration Technology for Labor and Cost Savings, Enabling High-Temperature Fermentation Even in Winter

In compost production, which relies on microbial activity, oxygen and temperature are essential elements. Easy Jet uses patented special nozzles to penetrate the compost with high-pressure air, 50 times stronger than conventional blowers, activating microbial activity. This system achieves high-temperature fermentation even in -30℃ conditions, significantly cutting labor costs and fuel expenses by eliminating the need for turning with heavy machinery.

Patented High-Pressure Nozzle with Easy Maintenance. Compatible with Existing Facilities

Easy Jet’s special nozzle prevents clogging and uniformly supplies oxygen throughout the compost. With minimal clogging, maintenance is simple. It can be retrofitted into existing piping, maintaining high-temperature fermentation even in winter.

High-Pressure Aeration Throughout the Compost for Stable Fermentation Year-Round

Oxygen deficiency during composting can lead to poor fermentation, odor issues, and uneven fermentation. Easy Jet’s high-pressure aeration uniformly delivers oxygen throughout the compost, ensuring sustained high-temperature fermentation even in cold conditions, producing high-quality compost year-round.

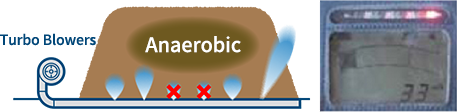

Conventional Method

Oxygen concentration 3.3vol%.

Easy Jet

Oxygen concentration 13.2vol%.

Advantages of Easy Jet

Stable performance even in sub-zero temperatures High-Temperature Fermentation Even in Winter

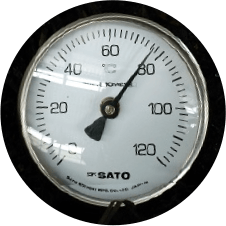

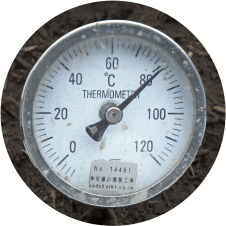

Since fermentation temperature is easily affected by outside temperature, fermentation temperature does not rise in cold regions during winter, causing poor fermentation. Easy Jet adjusts the moisture ratio by feeding an appropriate amount of oxygen evenly to the raw materials. It creates conditions conducive to microorganism activity, and even in sub-zero temperatures, the heat of fermentation can achieve temperatures of 75-85℃.

Reliable high-temperature fermentation even in cold conditions. Stable performance throughout the year.

Oxygen is also essential for odor control during fermentation High-pressure ventilation promotes aerobic fermentation and suppresses odors

Odors are a common problem in composting neighborhoods, but if aerobic fermentation is smooth, odor generation can be suppressed. Easy Jet’s high-pressure aeration from special nozzles supplies oxygen evenly even to poorly aerated materials. This promotes aerobic fermentation and is very effective in improving odor problems.

Forced ventilation with high pressure provides oxygen, promotes aerobic fermentation, and suppresses the occurrence of unpleasant odors.

Conventional Treatment Methods

-

Measured Value

Around 250

-

Odor Index

Equivalent to 7

Easy Jet

-

Measured Value

Around 50

-

Odor Index

Equivalent to 2

N=10*log(D/T)

Savings on Soaring Fuel Costs Unattended Compost Production with no need to cut back* to reduce costs

Turning (mixing) work, which is performed to supply oxygen to the materials and adjust moisture levels. Traditionally, heavy machinery was used to mix the materials uniformly and repeatedly. The Easy Jet provides oxygen to the materials evenly and maintains the appropriate moisture level, making turning unnecessary for composting. This is effective for labor-saving and cost reduction.

※It varies depending on the conditions.

Processing volume: 3 tons/day. Comparison based on 30 hours of turning time per month.

Conventional Treatment Methods

Fuel Costs※1 47,000yen/month

Labor Costs※2 ¥75,000/month

¥122,128

/month

*2: Calculated as 30 hours

× ¥2,500/h × 1 person

Easy Jet

Electricity

cost※3only

¥67,014

/month

No fuel usage, reducing CO2 as well

Annual

Approximately

45%

Cost reduction

(Assuming full operation at 73% load for 24 hours)

Short Fermentation Period, Increased Productivity Compost fermentation period shortened by 38%

By continuously injecting high-pressure air through Easy Jest, oxygen reaches every part of the material, promoting aerobic fermentation. As a result, turning the compost is unnecessary, a consistently high fermentation temperature is maintained, and the fermentation time can be significantly reduced. It shortens the fermentation period and produces high quality compost.

Our patented technology that delivers oxygen evenly at high temperatures produces high-quality compost in a short period of time.

Conventional Treatment

Methods

After 2 months of fermentation by conventional method. Undegraded material remains.

Easy Jet

Used for 1 month. Aerobic fermentation to the inside.

Calculated from the rate of progress of dry matter decomposition (Shimane Prefectural Livestock Technology Center Research Report No. 41_2010)

Special Patented design Special microporous nozzle eliminates clogging and simplifies maintenance

Conventional blowers are prone to clogging, resulting in an uneven supply of oxygen. Easy Jet sends air in from under the floor like a blower, but prevents clogging by specially designing the nozzle to blow high-pressure air out through a very small hole at the tip of the nozzle. This eliminates conventional problems and simplifies maintenance.

Patented

Jointly developed by Shimane Prefectural Livestock Technology Center

Easi Jet Introduction Video

Product Overview

| Size | Diameter 20mm, length 2m (per unit) |

|---|---|

| Processing Capacity | Processing Volume 0.5m3/day to 200m3/day or more |

| Electric Capacity | Depends on throughput |

easy-jet CASE

Case Studies of Easy Jet